Ranter

Join devRant

Do all the things like

++ or -- rants, post your own rants, comment on others' rants and build your customized dev avatar

Sign Up

Pipeless API

From the creators of devRant, Pipeless lets you power real-time personalized recommendations and activity feeds using a simple API

Learn More

Comments

-

// https://andyhemingway.files.wordpress.com/...

calling_the_herd(Hardware)

{

User[ ] = { @Condor , @nightowl , @7400 , @LuxARTS , @Crowns , @mngr , @JoshBent, @BadCompany , @shellbug , @c3ypt1c, @devTea , @rEaL-jAsE , @sbiewald , @Gregozor2121 , @Haxk20 , @Cozyplanes , @S-Homles-MD , @ewpratten , @ganjaman , @MisterArie , @No-Flux-Given , @aritzh , @dev1410 , @groenkek , @FrodoSwaggins , @Chill , @Fast-Nop , @codex653 , }

}

// If you want to me removed or changed to other category leave a reply -

Any Tip on how to change the resolution so it works right guys? I'm using Universal G-code Sender to control the machine.

-

@Condor Yah... Can't figure out this shit...

I can move exactly one mm by hand, or one stepper turn, but It should move mm's and not steps ... Fuck this lol

Last thing I figure out untill I start building my next one... -

@ganjaman Anet A8 with Auto level

The steppers move

But, when I order to move 64 mm it just does one full turn (meaning, it's moving 64 steps, not mm) -

Well... Hardcoded a G-code with a multiple of 51 per mm...

Was actually easy... Didn't program G-code for 3 years.

Just a Hello world to test... But now it's too late in the night for the noise :D

To bad this steppers won't last long :D With luck they will last untill my new Nemas arrive. -

Which slicer do you use? I bet your problem is related to microsteps or just wrong values in "how many steps/mm is it making"..

If you install e.g. Cura you can simply adjust this "steps/mm" value. If you want to write your own gcode (but fuuuuck, why?!) im sure you can adjust this value in the 3d printers firmware.

If you give me information about

The firmware you are using i think i can help you :)

P. S. if you already checked the right steps/mm configuration, then look on what current your drivers are adjusted. Maybe it is just too low current, so the stepper isnt able to work properly. -

https://components101.com/motors/...

There you go. Every Revolution is divided into 64 pieces. So if you tell the stepper "go 1 further", it will go 1 step further, not one mm.

So "+64" is one revolution, not 64mm.

If you want it to do 64mm, you would need a threaded rod with a thread pitch of 64mm/revolution :D you see.. -

@Haxk20 hey. Added you to the hardware herd. :D

It's loose enough... It wasn't working until I loosen it enough (motors didn't have pull, drivers didn't had enough power).

I know I'm killing the motors... But I'm having so much fun.

Should learn how to regulate the tension on the drivers, but don't even know the steppers tension, that's how cheap they are... It's 5V 64 steps and that's the info I find online... Even if they are behing powered by 12v lol. -

@borderless I'm using m8 Screws

M8 step = 1,25mm

Stepper turn = 64 steps

1 MM = 51 Steps

I'm using Universal G-code Sender with GRBL 1.1

If I Install what? Cura?

For the current, the steps are overpowered, and I don't have a multimeter right now to adjust it. They work at a good pace, Don't complain much...

the steppers are 5V 28BYJ-48, the GRBL shield is connected to a 12V 400W PC power supply. Hope to adjust later, when my dad arrives, so I can get my multimeter he borrowed a week ago.

Thanks for the site. I already saw like 20 datasheets (all the same) for the motor, researched everywhere... The problem is that Usually, no one uses these steppers with a screw driven CNC and GRBL because they are too week (they are usually used on plotters with bands instead of lead screw). But because the model I've chosen (H-bridged CNC) It works.

BTW the CNC I worked with for 3 years had these exact design, but with a 3m x 1,3m table. -

I think I should change this:

$100 = 250.000 (X-axis travel resolution, step/mm)

$101 = 250.000 (Y-axis travel resolution, step/mm)

$102 = 250.000 (Z-axis travel resolution, step/mm)

But If I do, and the calculations give me 16.000, the steppers can't handle it...

If this is the solution, then I must change something else, to compensate... because It tries to move too fast (like spinning 0.8 turn in a millisecond) and the gears will break -

@Haxk20 Well... That really sucks...

I can easily program G-code with a multiple of 51 (51 steps == 1mm) But that only works for really basic shapes and takes 10 times more.

There must be a config in the setup I can change, probably in GBRL before flashing, but I can't find it. -

everything fine now? :) so what did you do?

cura is a slicer for 3d printing. you load *.stl data in it, it spits out gcode. but tbh i just mentioned it because i thought you are not that much into cnc and stuff. thought maybe its easier to get it working by using a slicer with gui and so on instead of inventing own gcode. -

K, found the solution, but still can't figure out the calculations...

It was in front of me since yesterday.

I have to lower the feed rate to compensate for travel resolution lol

I'll post the results and the solution later, when I finish calibrating -

@borderless Nahhhh, I'm a cnc programmer and Operator...

Actually didn't get to do much programming because of the boss who fucked me in the first place.

I'll check cura, is it a CAM software? -

Can't find the fucking calculations....

So, I found out a few more things about the stepper:

28BYJ-48

Ratio 1/64

Steps in One Revolution: (360°/5.625°) = 64 Steps

Total steps = Steps in One Revolution x Gear Ratio = 64 x 64 =4096 steps

M8 = 1,25mm

1 mm = (4096 / 1.25) == 3276

This value isn't working

with X-axis travel resolution == 16.000 It moves 20mm when I ordered 15mm, so 3276 can't be it... -

Ok, adjusted the current...

Funny how the steppers work a lot better with the right corrent :D hope I didn't damage them much...

I think I found the right parameters... Last test is to check the distance. -

Ok, after hours of research I think I found the right parameters.

I needed to change the F (steps per mm) to compensate to the resolution (that's why the steppers would get stuck with the default speed of 500)

First, I changed the A4988 power rating to 600ma (the power the stepper needs), I would give a link but the tutorial is in Portuguese, still, there is more out there (this is necessary to not burn the steppers, still did lots of tests before finding info about this on my research)

Then, I did several calculations and hardware tests until it seemed right

I'll show only the calculations that seem right:

Steps in One Revolution: (360°/5.625°) = 64 Steps

Total steps = Steps in One Revolution x Gear Ratio = 64 x 64 =4096 steps

M8 = 1,25mm pitch -

Steps per mm = 3276,8

This should be the number of steps per mm, but I had to multiply per the number of phases, so

3277 x 4 = 13100

So, I had to change this values on config:

$100 = 13100.000 (X-axis travel resolution, step/mm)

$101 = 13100.000 (Y-axis travel resolution, step/mm)

$102 = 13100.000 (Z-axis travel resolution, step/mm)

$110 = 10.000 (X-axis maximum rate, mm/min)

$111 = 10.000 (Y-axis maximum rate, mm/min)

$112 = 10.000 (Z-axis maximum rate, mm/min)

$100s are the resolution per mm

$110s are the Speed, I'm giving it 10 mm/m (It can go up to 15, 16) to compensate for the extra effort.

programming the G-code for the final test now. -

Final test... Doing an engraving...

So.. the steppers are good enough for the CNC... or they will burn...

Burn modafoca Burn!!!

Let's hope not! :D :D :D :D

Related Rants

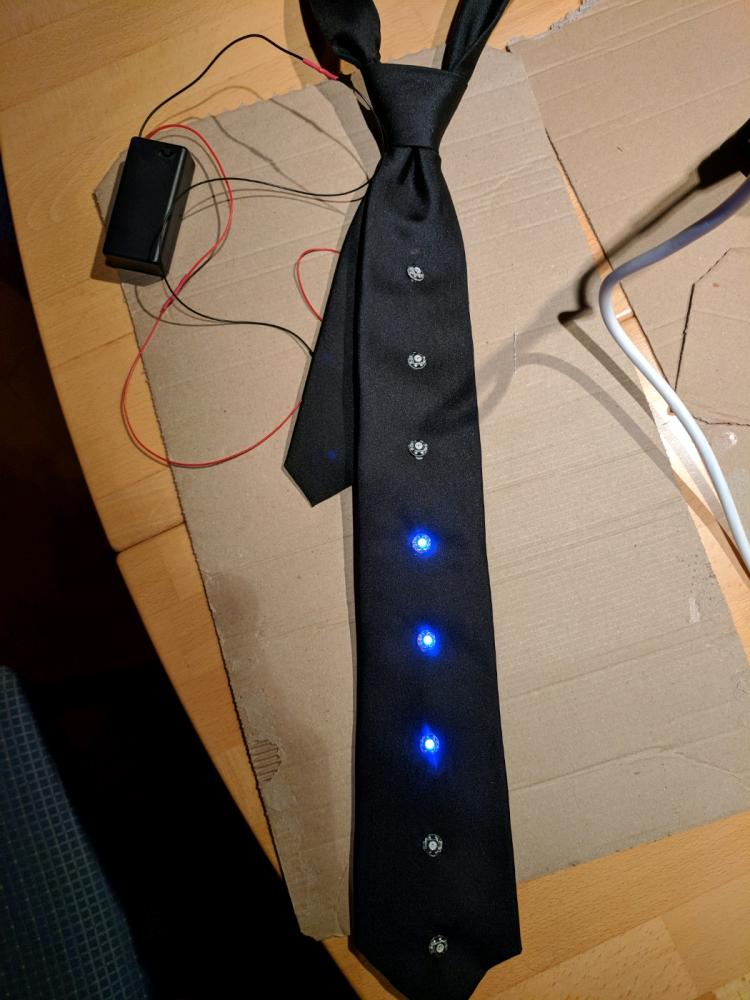

One of my personal projects.

Just trying something new ☺

One of my personal projects.

Just trying something new ☺ I have made this RGB LED tie. One of my friends and me had the idea at 2 am and now it has come to reality :D ...

I have made this RGB LED tie. One of my friends and me had the idea at 2 am and now it has come to reality :D ... Stress testing my new cnc, say Hello World roundy

Stress testing my new cnc, say Hello World roundy

!rant

Hey guys...

It's finally working.

Just needed to upgrade the drivers.

Using RGBL + 3 28BYJ steppers.

Just have one tiny problem and need help...

The resolution isn't right... Instead of moving mms, if I send a move of 64mm (one stepper revolution) it just turns one time instead of moving 64mm... Where are the settings to change this?

Btw this is the best birthday present ever, from me to me :-D also... My parents bought me a 3D printer, waiting for it to arrive... Me happy today

rant

rgbl

cnc

arduino