Join devRant

Do all the things like

++ or -- rants, post your own rants, comment on others' rants and build your customized dev avatar

Sign Up

Pipeless API

From the creators of devRant, Pipeless lets you power real-time personalized recommendations and activity feeds using a simple API

Learn More

Search - "pcb"

-

Six months ago my girlfriend broke up with me...

BUT since then I've...

•Found the wonderful world of devRant

•Gotten back into electronics

•Taught myself PCB design

•Gotten back into programming

•Made a discord bot

•Started teaching myself calculus

•Began building an ai for said discord bot

•Designed a wireless mesh networking NIC for the TI84+CE

Sure I feel like shit most of the time but before I did anyway but I've been super productive and it feels kind of nice45 -

!rant

Worked all day and got my embedded systems project working the first time! Bluetooth as well! 😁

It's a Fitbit clone that keeps track of steps that I did from scratch and writing the companion app from scratch as well in flutter/dart. Ask any questions if you're curious! 34

34 -

Not a rant, but I found this funny enough to share.

About two weeks ago, I’m contacted by a third party development firm that is responsible for building the next iteration of a control board were are developing. Alongside build of the PCB they were scoped to flash the firmware and verify all connected components.

During the call, they tell me they don’t have the resources to build our testing environment with the Ansible script I provided, and they don’t know if the updates they have made will work with our control system. Ugh...really...

I attempt to walk them through the 3 pretty simple commands to launch the playbook. Instead of listening, their project manager insists that I need to load up the environment and send them a ready to go system.

I quickly load up a RaspberryPi and prepare it for shipping. I hand the box to our shipping clerk and fill out the shipping request documentation. Then about a week goes by and this is where the story really begins.

I get an email from the same rep asking where the environment is, and I head down to the warehouse to inquire where the RaspberryPi might be. After speaking with the head clerk, we can’t seem to track down the package. I’m assured that they will find the Pi and send me the shipment update.

I pass the information along and after about a day and a half I still didn’t receive word back from the warehouse team. I load up another Pi and head back down to the warehouse. I follow up with the warehouse staff. They inform me that they have not been able to locate my package and another warehouse worker is called over. He says he hasn’t seen it, but they they were having a food day that day and he thinks more than likely someone ate it.

Like it didn’t even click at first but after a few seconds I realize that these guys have literally been looking for a pie for the past two days...and I JUST DIE.

After the 5 or so minutes of laughing I show them the newly flashed RaspberryPi, and of course they know exactly where the original one was.

It’s shipped out now, but wow. Also, it turns out the PCB manufacturing company didn’t even really need this and it was all a guise to hide that they are behind schedule and that they will not be able to finish the work scoped. FML!6 -

!rant

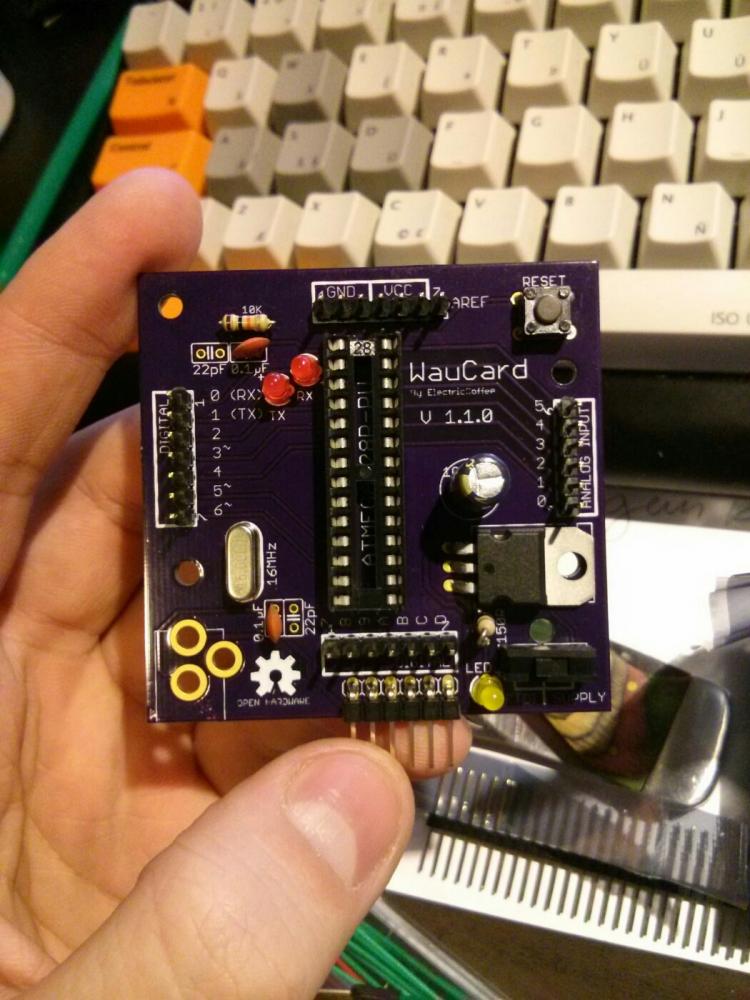

I once designed my own Arduino IDE compatible microcontroller, and even had the card manufactured.

Sadly I've yet to actually use it for anything, but hey, achievement unlocked, right? 15

15 -

Although I love developing I always thought that there was something missing.

I learned Java but didn't really like it. I had spent quite some time with web development and enjoyed it but I felt like developing with JavaScript was too high level and I felt the same for Python.

So I started learning the most awesome programming language: C

I just love that I have so much control over everything and that the language is so compact and gives you just the right amount of tools you need.

I also love physics and electronics a lot and it feels awesome to first build something and then program it.

I am looking forward to design a PCB (printed circuit board) and write code for an AVR microcontroller like the Atmega328 (most arduinos use this one).

Picture of the project I am working on. 10

10 -

Woohoo! 32k achieved!!! Finally I can post some new rant without risking some sudden overshoot 😁

So putting celebrations aside for a minute, a while ago I've noticed a tingle when I stroke my finger across metal areas of my tablet, or the sides of my phone (which probably has metal near it too) while it's charging. And it's been bugging me ever since.

Now, some things to note are that it only happens when my feet are touching the ground though slippers, and that the frequency is so low that I can actually feel the tingle when I slide my finger across the material. This to me at least seems like electricity flows through me into ground, and touching the ground directly provides a path so easy for the electrons to run away that I don't feel it at all. But if I lift my feet off the ground entirely, I just get charged up and after that, nothing else happens.

So those are my ideas. The answers on the subject on the other hand.. absolute cancer. Unsurprisingly, most of them came from Apple users. Here's some of them.

https://discussions.apple.com/threa...

- I've not noticed it, but if you're concerned bring the phone to Apple for evaluation.

- Me too facing same problem.. did u visit apple care?

And one good answer at least...

- google emf sensitivity, its real. You are right, there is a small current flowing through your body, try to limit your usage. The problem with this issue is those who aren't affected (lucky ones for now) will tell you these products are 100% safe. To a degree they are, i used my ipod touch for about 2 years straight vwith virtually no symptoms. then the tingling started and it gets worse.You will get more sensitive to progressively less powerful things. I dont want to scare you but just limit your usage like i didnt do 🙂

Overall that discussion was pretty good actually, aside from "bring it to the Genius Bar, they'll know for sure and not just sell you another unit". But then there's Reddit.

https://reddit.com/r/iphone/...

- Ok, real reason is probably that the extension cord and/or outlet is probably not grounded correctly. Either that or you are using a cheap knockoff charger.

Either use a surge protector and/or use the authentic Apple Charger.

- It's not the volts that hurt you, it's the amps

- I think you are in deep love with your phone. That tingling sensation is usually referred to as "love" in human language.

- Do less acid, I would advise.

Okay, so that's the real cancer. Grounding issue sounds reasonable despite it being wrong. Grounding is actually not needed when your charging appliance doesn't have any exposed metal parts. And isolation from high voltage to low voltage side actually happens through things like routering holes into the PCB, creating spark gaps, and using galvanic isolation through things like optocouplers. As for a surge protector? I'm using them to protect my PC and my servers, but the only purpose they serve is to protect from.. you guessed it.. voltage surges, like lightning bolts hitting the grid. They don't do shit for grounding or reducing this tingle! What a fucking tool.

It's not the volts that kill, it's the amps.. yeah I'm sure that the debunking of that is easy to find. Not gonna explain that here. And the rest of it.. yeah it's just fucking cancer.

Now what's the real issue with this tingle? It's actually a Class-Y rated (i.e. kV rated) capacitor that's on the transformer of any switch-mode power supply, including phone chargers. If memory serves me right, it helps with decoupling the switching noise and so on. But as it's connected to the primary side of the transformer, if the cap is sufficiently large and you are sufficiently sensitive, it can actually cause that tingle by passing a fraction of the mains electricity into your body. It's totally safe though, as the power that these caps pass is very small. But to some, it's noticeable.

Hope you found this interesting! And thanks a lot for bringing me to 2^15. I really appreciate it ♥️ 14

14 -

So I get to work this morning and see this interesting little contraption on my work colleague's desk.

Safety first: make sure there's a warning sign... Lol.

No idea what he's doing with it though, guess I'll find out later. 6

6 -

My PCBs that I designed arrived today! They're just to test how to use the Atmega32u4 microcontroller before I make a keyboard using it :)

10

10 -

Just thought I'd share my current project: Taking an old ISA sound card I got off eBay and wiring it up to an Arduino to control its OPL3 synth from a MIDI keyboard. I have it mostly working now.

No intention to play audio samples, so I've not bothered with any of the DMA stuff - just MIDI (MPU-401 UART) and OPL3.

It has involved learning the pinout of the ISA bus connectors, figuring out which ones are actually used for this card, ignoring the standards a little (hello, amplifier chip that is wired up to the +12V line but which still happily works at +5V...)

Most of the wires going to it are for each bit of the 16-bit address and 8-bit data. Using a couple of shift registers for the address, and a universal shift register for the data. Wrote some fairly primitive ISA bus read/write code, but it was really slow. Eventually found out about SPI and re-wrote the code to use that and it became very fast. Had trouble with some timings, fixed those.

The card is an ISA Plug and Play card, meaning before I could use it I had to tell it what resources to use. Linux driver code and some reverse-engineering of the official Windows/DOS drivers got me past this stage.

Wired up IRQ 5 to an Arduino interrupt to deal with incoming MIDI data, with a routine that buffers it. Ran into trouble with the interrupt happening during I/O and needing to do some I/O inside the handler and had to set a flag to decide whether to disable/re-enable interrupts during I/O.

It looks like total chaos, but the various wires going across the breadboard are mainly to make it easier to deal with the 16-bit address and 8-bit data lines. The LEDs were initially used to check what addresses/data were being sent, but now only one of them is connected and indicates when the interrupt handler is executing.

There's still a lot to do after that though - MIDI and OPL3 are two completely different things so I had to write some code to manage the different "channels" of the OPL3 chip. I have it playing multiple notes at the same time but need to make it able to control the various settings over MIDI. Eventually I might add some physical controls to it and get a PCB made.

The fun part is, I only vaguely know what I'm doing with the electronics side of this. I didn't know what a "shift register" was before this project, nor anything about the workings of the ISA bus. I knew a bit about MIDI (both the protocol and generally how the MPU-401 UART works) along with the operation of a sound card from a driver/software perspective, but everything else is pretty new to me.

As a useful little extra, I made some "fake" components that I can build the software against on a PC, to run some tests before uploading it to the Arduino (mostly just prints out the addresses it is going to try and write to). 46

46 -

A PCB I designed on the job over the last weeks shipped today! A benefit of hardware is the haptic element you have at the end of the design process - you made something touchable. (I am proud.)

Also, errors made earlier in the design process are permanent now. But other than on my software my design got reviewed, so I'm optimistic it'll not contain many if any.

I'm on vacation right now for moving stuff but I'm looking forward to do the "pick'n place" on monday. Soldering manually is quite relaxing for me, you should try it, too! ;)

In other news, I'm no longer sleeping on the floor in my home-office while the paint is drying in other rooms.

I already moved the most of my stuff - books and tech equipment are the worst - and I moved my furniture yesterday.

My new roommates are considerably quieter and my sleeping rhythm is slowly shifting back to normal.10 -

Today we presented our project in Embedded Systems. We made our so called "Blinkdiagnosegerät" (blink diagnosis device) which is used to get error codes from older verhicles which use the check enginge light to output the error. (for reference: http://up.picr.de/7461761jwd.jpg ) This was common for vehicles without OBD.

We made our own PCB, made a small database for 2 vehicles and used a Suzuki Samurai instrument cluster for the presentation (hooked up to an Arduino UNO and a relay for emulating some Error Codes)

Got an 1.0 (A) for the project. Feel proud for the first project done in C++ and making our own PCB. So no rant, just a good day after all the stress in the last weeks doing all assignements and presentations.

Next week we hopefully finish our inverse pendulum in Simulink and then the exams are close. :D 15

15 -

//An okay long rant..

So i work at this small robotics start-up company I Copenhagen.

The first dumb part is that it only uses interns as staff, because then they don't need to pay people. (I am working part time, for free. Just to get experience (I am only 20 btw))

So.. I often get into an argument with my boss, since she is a designer with a "passion" for robotics (she has no clue how to do anything related to the work) But I often try to explain to her some current limitations in the staff, and what is possible for us to do, but she will never listen. She really wants us to design our own microcontroller board PCB, and she want it at the size of a coin. However when I tell her that none of the, non paid works has the experience or education to design such a thing, she never wants to acknowledge it, and it really pisses me off.

And her dad, who is the top boss, only care for esthetics when he is making a work environment, which is dumb when we just need to develop stuff...

Sorry if the rant was too long but had to get it out..8 -

soldering on a pcb is just as stressful as programming. u solder everything and u test it out and then it doesnt work like its designed to. its just like compiling it and a lot of errors are detected. the worst part of it, you cant detect the errors as soon as u try it out. you have to find where exactly in this kind of mess is the error:

6

6 -

I forged a katana once, under the supervision of a swordsmith. Nothing super special like damascus patterning or anything, but the cutting edge was pretty sharp.

Ugh sorry, lame word jokes.

In terms of software...

Microsoft Office Ribbon (cutting edge at the time, lol). Only as a maintenance drone on a bunch of manual search-and-replace work and merge conflict resolving.

Ariane 6 family of rockets (Welding X-rays and other DICOM quality assurance).

Software for continuous flow chemistry, developing microfluidic PCBs to perform Elisa immunology assays during the Mexican flu outbreak. Idea was to eliminate the need for microplates, expensive robots, microwell washers, etc — just have blood plasma, enzymecoated nanoparticles, antigen, conjugated detection reagents and substrates flowing programmatically through a PCB with a spectrophotometer built in.5 -

I wanted to play Pirates under DOS back then, but it didn't have the left-handed mouse button switch like Windows.

So I opened the mouse, scratched the PCB button lines away, soldered wires cross-over, and had a left-handed mouse also under DOS.3 -

IDK, there's something about PCB circuits with all the components on it... For some reason I find them very calming, I think they could even help me with my anger management and/or sleep problems (if I had any).

They are so nice and neat.. so strict and in order. Everything has its own place and its own path. Everything in there has its purpose. That's so nice :)

// triggered by https://twitter.com/iXsystems/... random just a tag that's weird how many tags can i assign? relax circuitry umm.. okay..? pcbgasm ocd maybe? wtv pcb order4

random just a tag that's weird how many tags can i assign? relax circuitry umm.. okay..? pcbgasm ocd maybe? wtv pcb order4 -

When you're supposed to make a pcb for this SMD component, but when you etch you realize it's the wrong footprint.

Ended up soldering enamel wire tomthe chip.

hope it works 4

4 -

Didn't had to fix anything (so far). But took my dev laptop to show all the projects I've been working on to the dad of my girlfriend and he showed me his projects.

He's not mainly a dev, but an electrical ingenieur. He designs his own pcb boards (with 8bit processors on them, as "that's more than enough power to do almost anything!") and then programs that stuff with basic (he writes his own firmware for it).

He also creates desktop application to get data off the devices using Delphi.

Love that guy and have a shittln of respect for him!1 -

Short story for the one interessed in the image: when we change idea we change the whole idea. And it is likely to happen very often. Sometimes twice a day, every day, for a week.

Long stort:

I am hopeless:

I am an IT university student, i know how to program and how to search for a fucking manual, but i am dealing with eletronics and PCB...

I have to make the firmware for a board (atmel things) and it have to talk via spi with some other devices (it is slave of one, and master for all the others(i will use two spi channels)), this should be easy...

I am have no senior to ask to, all i have is google and i found problems in every thing i try to do, every - fucking - single - one!!!! I know that the solution is always of the "you have to plug it in" type, but

NEITHER GOOGLE IS BEING OF HELP!

Let me explain this morning pain:

i can't add libraries in atmel studio, something wrong with the asf wizard, i have only found a tutorial that says what buttons press to solve my problem... I DO NOT HAVE THIS BUTTONS!!!

And the library i wanted to add is the one to make the board talk with the computer on his COM port... (And have some debug message...)

And the wizard gives problem because i created the project using an online atmel tool...

YES, i tried to create a project with asf and then add the files given by the online tool.... THEY DO NOT COMPILE, I SHOULD HAVE TO MESS WITH A 400 LINES LONG MAKEFILE, that is anything but human readable...

I haven't even look for anything spi related this morning

I am even forced to use windows, because every question in the forums, or every noobbish tutorial is based on it...

And then i find the tutorial with the perfect title, holy shit this is the thing i truly need!!!!! It says how to open a file. And then stops. WHAT ABOUT THE THING YOU WERE TALKING ABOUT IN THE TITLE??????

This project is the upgrade of a glue-pump based on an atmega328 (arduino uno processor), that is currently being produced and sold by our "company" .... .... That is composed by me and the boss.

He is a very nice and and smart person, he tries to give me ideas for the solution, if i cannot find out how to do something we can even change a lot of specifics of the project (the image shows our idea-change) and every board has some weeks of mornings like the one described above (i work only in the morning).

I am learning a very lot of things...

But the fact that every thins i try fails is destroying me, what would you do in my place?

Ps. Lot lf love for the ones who made it until the end <3 6

6 -

Ooh come on .... The fluecent tube of our bathroom mirror was broken. So my girlfriend bought a new one. Still didn't work. So it must be the starters. Nope they work. So I took the damn thing apart completely and ripped out the PCB and meassured every transistor, diode and capacitor. And even replaced one that gave some fishy values just in case. Still didn't work. Then I opened the side door of this mirror and found a switch that I must have switched off by accident ... Switched on: lights on 🤔🤗😌2

-

This MOTHERFUCKER was hiding from me for three FUCKING DAYS now! All the damn time I had corrupt display memory cause of it!

Context: CS and DC were accidentally swapped on the PCB! Not a hardware issue thou. The pins can be remapped in software. 7

7 -

:3 I'm soooo happy right now! My friend asked me to help her get started in designing circuits and making her own PCBs. Great motivation for me to write a few articles on it 😊... Honestly I would have just asked her to marry me right on the spot if she wasn't a lesbian and didn't have a girlfriend already.

...maan, it bugs me a lot: super cute, same interests, really really intelligent and knowledgeable, great character... Why must everyone care about gender? :( (I don't - just for the context...)4 -

New robot in development!

Much better than my old one:

- sturdier base/wheels further apart

- got a custom designed PCB printed for it

- 18V motors 2

2 -

Today I Fucked Up. I tried to do something involving hardware.

I tried to fix my mechanical keyboard by myself with no thought towards how electronics work. My first time using a soldering iron and trying to fix something myself.

I went from needing to replace one key to burning some plastic, failing to get new solder onto the parts to attach the new key to the PCB and getting solder where I didn't want it to needing a new keyboard because I think I've fried some stuff so badly half the bottom row of keys no longer works.

Fucking wonderful.

Guess it's time to buy a new keyboard.

Sigh. 4

4 -

I want to make an AI bot from scratch. Where do I start? Which languages should I know? What IDE should I use?10

-

Hey hardware hackers, just wanted to let you know that seeedstudio offers free PCB assembly. I got 5 pieces of the PCB in the picture for 30 USD manufactured, assembled and shipped (including BOM costs), the also included 5 additional empty PCBs. However I paid another 30$ for customs and DHL customs handling (I'm inside Europe) ... But still, for assembly it's a great price, took around 4 weeks. Just upload the BOM and you get an instant quote. If you are curious, it's a simple board for an ESP32 with some mosfet drivers and two DC-DC converters.

https://seeedstudio.com/free-assemb... 4

4 -

What the hell has happened to Hewlett Packard?

They used to make the best notebooks around. 10-15 Years ago, basically all notebooks my family bought were from HP. These devices lasted for at least 6-8 years each.

Now I have a fucking expensive OMEN series notebook failing after 2 years with the most embarrasing hardware problems: Once a shielded piece of plastic from the bottom broke off and made a short on the mainboard, next time the way too thin power line that goes from the power plug to the PCB was placed alongside a sharp metal piece that damaged the isolation and again produced a short. When the display is moved, the webcam disconnects, which is also a hint at the production quality.

From my daughter's HP notebook the Display just broke off after like 18 months of use. When we brought it to service I asked the guy whether this happens a lot, he was like "I have 6 other notebooks of that type with the same problem in repair right now". After a repair that took forever because they couldn't get the proper replacement parts, the integrated webcam has died.

Never ever going to buy anything from this shitbrand again.4 -

Best co-worker is my elder brother, he is electronics & communication engineer. Working on robotics project is too much fun. He handle the haredware i.e electronic circuits design in PCB where as programming work is left for me.1

-

Today I almost had an engineering orgasm. I'm designing a Eurocard PCB for a Subrack. All components already came with a 3D model within the EDA software. I could therefor export the entire PCB to an STL and print it out for a fitment check. Also the Subrack Vendor has an online designer for the front. You guessed it! It can be exported to CAD and Printed. Man I LOVE the current state of electrical and mechanical engineering. This is such a fucking game changer! I really hope the electrical side checks out thou as prototype manufacturing is expensive! Like 4k can go down the drain for just 5 boards.1

-

Spent one hour looking for an error in my PCB only to find that the symbol and the actual component of a part in the parts library differ in terms of pin numbers. The colleague who created the part is already retired.1

-

After debugging my embedded code for five hours my teammate just sent me a message "I just commited the latest PCB". Well thanks, after looking at the new layout I got the initial code working by just changing one variable!

-

Scratch away the PCB trace that was initially connected and solder a wire straight to the IC pin to connect it it to the place you want1

-

Hi All, I used to be a user on devrant while I was in middle/highschool. I kinda forgot about it for a long time but I rediscovered the app when I saw a sticker on a retired laptop.

Quick Intro

CS Student at Drexel, 4th year out of 5

I want a career in software and want to reserve

hardware related things for hobbyist endeavors.

I made a 3x3 macropad with a pi pico including designing and printing the pcb, soldering all the components, and then writing the firmware (micropython blegh). My goal is to daily drive a 75% keyboard of my own making

Currently my main keyboard when I'm using my desktop is a Keychron v1 with Haimou Hearbeat silents and sugarplum keycaps (lmk if you want pics)

I like martial arts, while I practice BJJ, I am interested in Judo and Muay Thai as well.

I like History and Linguistics

The above point got me into power metal, mainly sabaton and then bands similar to it

Ill finish off with some nerdshit

I use a framework with fedora as my daily driver, I am a neovim enjoyer, my steam deck is gathering dust, and I have more Pi's than I know what to do with.3 -

I was trying to recover an external hdd, which was not spinning at all.

I started by changing the enclosure, using the SATA port, using another enclosure, now the only possible culprit is pcb.

On testing with multimeter I figured TVS diode was damaged, and since I don't have immediate access to a new pcb, I opened one of my old hdd and desoldered pcb from there and using wires I attached this salvaged TVS diode to the pcb.

It didn't work.

During the research, I came across the fact that different manufacturers make different pcbs, what the hell, I wish there could be some standardisation so people could just swap things easily instead of finding another hdd of the same model just to salvage the pcb.2 -

Is it safe to assume that Dell's power button PCB-s all communicate the same way? They all have a single button and four wires.2

-

Okay soo I’m not a database guy.. I’m an embedded engineer but I’m helping one of my interns make a hardware tracking database... so we are tracking assembled products (dev samples).. but also tracking the pcbs within the product.. depending on the product it might have more than one pcb or contain other components to track.

The question is how would I set up the relationship in the tables, so depending on the say “type id” of the product it would link to a table full of feilds specfic to that “type”.. say the product is of type phone and has a pcb of this and a camera of that.. blah blah blah.... but say another product is of type “washing machine”.. which has no screen, it has a different pcb, but also has other things..

There would be a type table .. washing machine, phone, tv, camera, pcb, ecu.. etc.. but those type would need their own tables...

I guess the question is how to relate a field to different tables depending on the value of the field... is this portion all done thru query results and logic rather than pure data base schemas?

What would be the question in terms of database lingo to google search the answer lol2 -

So, got my first ssd. It's so freaking light 😳. I hope it's not just the outer casing without the internal PCB 🤪.

No, i wasn't living without an ssd. It's just to revive my 5 year old laptop 😅